Innerspring Support Cores

- By NW Bedding

- •

- 30 Oct, 2016

- •

What you need to know about an innerspring mattress!

Coil Physics

- High carbon steel wire is shaped in the form of a helix to provide a torsion resistance to movement along its vertical axis

- The shape is electrically heated to temper the wire and re-align its internal molecular structure along the path of the shape.

- The steepness of the wire path, or "pitch", in relation to the vertical axis is one determinate in how "firm" the coil will feel. The steeper the pitch angle (over a fixed total height), the firmer the coil.

- The gauge of the wire is also a determinate in the stiffness of the coil. A thicker wire (lower numbered gauge) will result in a coil that is stiffer than a coil formed from a higher gauge wire (thinner wire).

- The number of revolutions that a coil makes around a vertical axis is referred to as "turns". Increasing the amount of turns for a given coil height reduces the pitch angle and forms a coil that is "softer".

- The wire pitch angle can also be affected by reducing the barrel diameter of the coil such as in Leggett & Platt's Power Edge® coil

Innerspring Mattress Types:

1. Bonnell

First developed in the 19th century from the buggy spring, this particular coil configuration is the most widely "consumer tested" innerspring on the market.

Its "knotted" hourglass shaped coils ") (" are "laced" together with spun "helical" wires at the top and bottom ("foot") of each coil. The entire shape of the unit is defined with heavier gauge "border wires" that are generally clipped to outer perimeter coils.

In certain configurations (coil count, wire gauge) this unit is extremely durable and can take quite a number of years of rigorous use before eventually losing its "temper memory".

Because of its wide availability due to many sources of supply (including offshore manufacturers) this unit's pricing is very competitive and, therefore, is used quite frequently in promotionally priced products. But, because of its durability, it is also used quite frequently in hotel and motel applications, university dormitories, and, yes, even in upscale bedding.

2. Offset Units

- Very similar to the Bonnell unit, the "knotted" offset coil takes the round end of the Bonnell coil then straightens one side of it resulting in a "D" shape. This shape results in a better hinging action when the coils are laced together

- Subsequent iterations of the offset coil resulted in either the "knotted" double offset (two straight edges) or the "free-end offset" coil such as in Leggett & Platt's Luraflex™ unit or Leggett & Platt's Symetrics® product or in Hickory Springs® InnerACT™ coil unit.

- Many of these type units have head-to-toe helical lacing which allows for "zoning" of the unit by spacing coils further apart (less dense configuration resulting in a more flexible area) or closer together (more dense configuration resulting in firmer support areas).

- The InnerACT™ and Symetrics® units feature adjoining coils whose "turns" of wire are going in opposite directions. For any given coil with the "turn" going in a counter clockwise direction, the coils on either side will have a clockwise rotation. The rationale of the engineering behind this design is to help all the coils compress and release in a more vertical direction and, thereby, reduce motion transfer to your sleeping partner.

- A newer, proprietary unit manufactured by Leggett & Platt is the VertiCoil® unit. It has been designed with wire using a higher carbon content that allows it to achieve greater strength in the annealing (tempering) process. Because of the wire, they are able to produce a coil that only requires 4 ½ turns for a unit that is 7 inches in height.

3. Continuous Wire

- As the term implies, "spirals" (as opposed to coils) are formed from one continuous piece of wire and are again joined together with helical wire to form the innerspring unit.

- A spiral might only have 2 ½ turns of wire, but they gain a lot of strength by being connected to other spirals in a type of trapezoidal shape.

- Leggett & Platt produces two distinct continuous wire units, the Mira-Coil (principally used in Serta's Perfect Sleeper® products) and the Superlastic® unit

4. Encased Coils

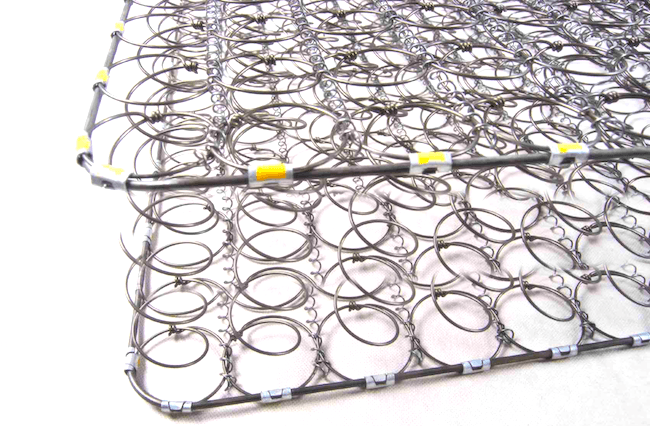

- Also known as a Marshall Coil ®, or Simmons' Pocketed Coil ®, individual coils are encased in a nonwoven fabric to form coil strands.

- These strands of coils are then attached to each other, generally, using beads of hot-melt adhesive.

- Because the coils are not joined to each other at the top and bottom of the coil with helical wire or any other sort of mechanical connection (the beads of glue holding the coils together are, generally, 3 lines about an inch apart at the center of the coil encasement), the transfer of motion from one sleeper to the other is greatly minimized.

Wire Gauge:

- The gauge system used in the bedding industry is the Washburn & Moen (W&M) system.

- Generally, the higher the gauge number, the thinner the wire. To compare how much steel (volume) is used in each gauge, you can compare the difference in cross-sectional area. For instance, a 13 gauge wire has 4.242 mm2 of area and the 14 gauge wire has 3.237 mm2 of area. Therefore, there is 4.242/3.237= 1.3105 or 31% more steel contained in each cross-section of wire.

- For a given coil shape, a lower gauge wire will withstand a greater load over a certain compression range (say compressing a 6 inch spring to 5 inches). Conversely, the coil will not compress as much given the same load. Ergo, the lower gauge coil will be firmer and, generally, more durable.

Coil Count Comparison:

- When you take all of the parameters listed above, i.e., coil shape, wire pitch angle (turns of wire around a given axis) and wire gauge, it becomes virtually impossible to make a comparison between different types of innerspring units based solely on the number of coils used in a unit of similar size.

- Rational comparisons can be made however. For instance, a 312 13 gauge Bonnell unit can be termed as a "better" unit than a 312 13 ½ gauge unit. A 336 13 gauge unit is "better" than a 312 13 gauge unit. But it becomes more difficult to compare when you vary both the coil count and also the wire gauge at the same time. For instance, is a 510 15 ga Bonnell unit “better” than a 364 12.75 gauge unit? Kind of hard to say. The 510 has much smaller diameter coils and skinnier wire. The shape of the coil is a bit straighter rather than hourglass shaped.

- To complicate matters even further, some retailer or manufacturer a number of years ago decided, for marketing reasons, to quote coil counts in queen size rather than the industry standard of naming a unit based upon its full size coil count. So a 312 Bonnell unit is often quoted as having "390 coils" which is the number of coils in a queen sized unit.

Edge Supports:

- With the exception of the individually fabric encased coil configuration, most spring units have coils that are mechanically attached to each other. Therefore, when you exert a load on a particular coil, the other coils surrounding that coil have a portion of the load transferred to them and they help support the downward force.

- This phenomenon holds true until you reach the edge of the spring unit where there are no additional rows of coils to help support the load beyond the perimeter of the mattress unit.

- To provide additional support at the edge of the mattress, various types of supports can be added. These supports can be made of rigid styrene foam in several shapes or various types of steel spring or torsion modules.

Zoning:

- Certain innerspring and encased coil units are "zoned". In other words, they have different support characteristics within different zones of the unit. The coils are more giving or flexible in one zone and more firm and supportive in another zone.

- Zoning can be accomplished in a number of ways:

- Head to foot helical wire allows different spacing of coils or continuous spirals. If they are spaced farther apart, the zone becomes more pliable. When spaced closer together, the zone becomes firmer.

- Innerspring units with side-to-side helical wire or encased coil units can have different gauge coils to create firmer or more pliable zones. Since the advent of the "automated transfer machine" positioning coils to be attached together with helical wire, multi-gauge innersprings units with side-to-side helical connections are virtually non-existent. Prior to the invention of that machine, the coils were laid up by hand making it possible to position two different coils in different rows of the same unit. It is still feasible for encased coils, however, to have this type of zoning.

- For units with identical coils, it is still possible to create zones by placing "belly bands" of a primary insulator (see below) or foam on the surface of the unit. For instance, a 5-zone configuration (soft-firm-soft-firm-soft) can be created by covering a unit in a pliable insulator such as a polypropylene mesh and then adding two 12"-14" pieces of a more rigid insulator in two zones. Steel bands or wire mesh has also been used to create firmer zones on a unit.

- Instead of adding items to the surface of the unit, rigid components can be inserted between rows of coils within the unit. Restonic ® had a process that added rigid styrene components to the center of the innerspring unit. Over time, these components became too expensive so they converted to shoving regular poly foam between the coils which, basically, did nothing.

- For quite a period of time, it was considered prudent to beef up the center third of the innerspring unit to assist in supporting the greatest mass of the sleeper's body. the torso and hips. However, it has been proven that greater spine alignment can be accomplished by just the opposite. With more flexibility in the center of the unit, the sleeper's hips and/or buttocks can more easily compress the springs and help straighten the spine in relation to the upper torso area when sleeping on the side or on the back. Such zoning does not really help, though, for a sleeper that prefers a stomach position.

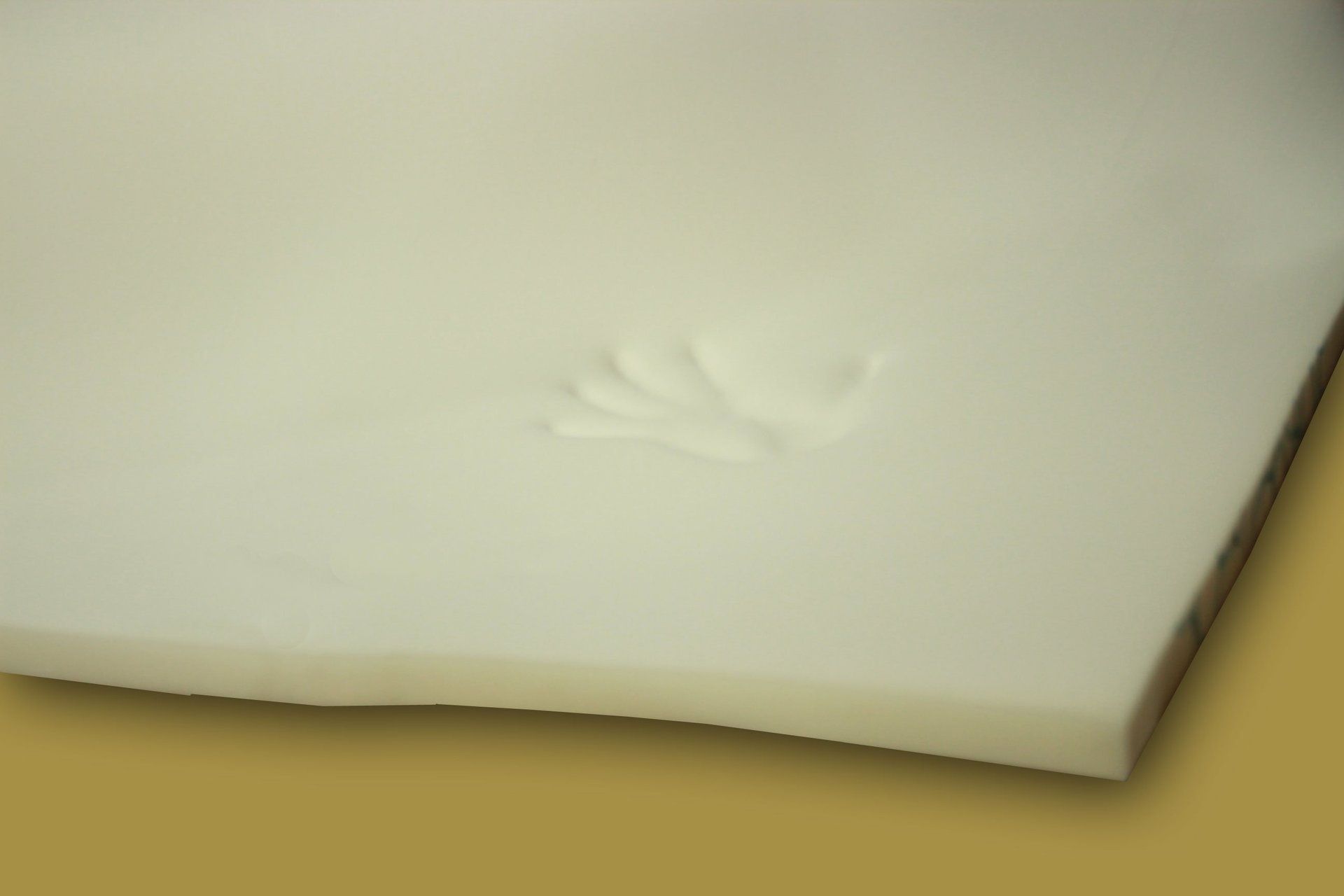

Carpenter, a leading supplier of foams and fiber has invented a new cushioning foam they've dubbed Serene™. The new foam features billions of microscopic air capsules which act to enhance support properties while reducing pressure on critical areas like hips and shoulders. Serene™ is less temperature sensitive than memory foams. In fact, our plant manager took a 6 inch cube of Serene™ and put it in his freezer for 3 days. The foam compressed as if it had been kept at room temperature.

Serene™ has been demonstrated to dissipate heat faster than memory foam. Serene™ is far more durable than a comparably dense piece of memory foam and is as or more durable than a memory foam that is almost twice as dense.

Because of these characteristics and more, we have been experimenting with some prototypes featuring a hybrid design of a stratified core with a thick piece of Serene™ on top. We have also been experimenting with combinations of Serene™ and Talalay Latex. Those combinations have produced some incredible feels and will be available soon both on our retail floors and at our dealers.